Sonipat, Haryana, India

Sonipat, Haryana, India

Sonipat, Haryana, India

Sonipat, Haryana, India

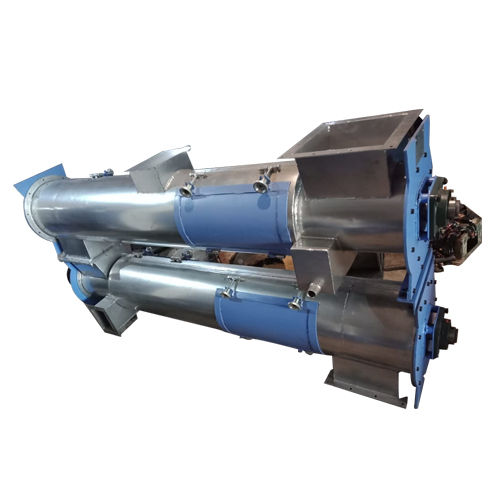

Hammer Mill Beater

Product Details:

- Type Hammer Mill Beater

- Material Alloy Steel

- Feature Highly Wear Resistant, Durable, Corrosion Resistant

- Feeding System Manual or Automatic

- Size Custom as per requirement

- Technology Forged and Heat Treated

- Color Silver/Grey

- Click to View more

X

Hammer Mill Beater Product Specifications

- Silver/Grey

- Alloy Steel

- Manual or Automatic

- Custom as per requirement

- Highly Wear Resistant, Durable, Corrosion Resistant

- Forged and Heat Treated

- Hammer Mill Beater

- 1.2 to 2.5 kg (varies per size)

Hammer Mill Beater Trade Information

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- as per market demand Per Day

- 3 Days

- All India

Product Description

Get superior performance with the Hammer Mill Beateryour go-to solution for crushing, grinding, and pulverizing in agricultural and industrial settings. Find this popular beater, crafted from alloy steel and forged using advanced technology for soaring durability and enlightened corrosion resistance. Its polished, smooth finish and sharp, precision-ground edges provide lofty efficiency. Compatible with most hammer mill models, it offers a universal fit. Sizes are customizable, ensuring the right fit for your needs. Popular among dealers, manufacturers, and exporters throughout India. Packaging options include robust boxes or wooden crates.

Competitive Edge & Specific Applications

Experience lofty operational efficiency with Hammer Mill Beaters precise, sharp-edged design and soaring hardness (48-52 HRC). This beater stands out in the market with its highly wear-resistant and corrosion-resistant properties. Find superior adaptability for both manual and automatic feeding systems in diverse environments. It is ideally suited for crushing and grinding agricultural produce as well as industrial raw materials, making it an enlightened choice for manufacturers, traders, and suppliers seeking dependable, long-lasting components.

Sample Availability, Shipping, and Packaging Advantage

Boost your market value by opting for Hammer Mill Beater samplesavailable to help you evaluate quality before bulk investment. Enjoy express shipping through popular FOB ports, ensuring minimal outlay and timely dispatch. Packaging is thoughtfully done, using either durable boxes or sturdy wooden crates to safeguard your order in transit. Dealers, distributors, and wholesalers benefit from streamlined logistics, making your acquisition process seamless and dependable, no matter your order size or destination.

Competitive Edge & Specific Applications

Experience lofty operational efficiency with Hammer Mill Beaters precise, sharp-edged design and soaring hardness (48-52 HRC). This beater stands out in the market with its highly wear-resistant and corrosion-resistant properties. Find superior adaptability for both manual and automatic feeding systems in diverse environments. It is ideally suited for crushing and grinding agricultural produce as well as industrial raw materials, making it an enlightened choice for manufacturers, traders, and suppliers seeking dependable, long-lasting components.

Sample Availability, Shipping, and Packaging Advantage

Boost your market value by opting for Hammer Mill Beater samplesavailable to help you evaluate quality before bulk investment. Enjoy express shipping through popular FOB ports, ensuring minimal outlay and timely dispatch. Packaging is thoughtfully done, using either durable boxes or sturdy wooden crates to safeguard your order in transit. Dealers, distributors, and wholesalers benefit from streamlined logistics, making your acquisition process seamless and dependable, no matter your order size or destination.

FAQs of Hammer Mill Beater:

Q: How do I determine the correct size and hole diameter for my hammer mill beater?

A: The size and hole diameter are customized based on your specific hammer mill model and requirements. Simply provide us with your machine specifications, and well ensure a perfect, universal-compatible fit.Q: What materials are used in manufacturing Hammer Mill Beaters and what benefits do they offer?

A: Hammer Mill Beaters are forged from high-grade alloy steel, providing soaring hardness, superior wear, and corrosion resistance. This leads to extended service life and reliable grinding or pulverizing performance.Q: Where can I purchase the Hammer Mill Beater and are samples available before placing a large order?

A: You can get Hammer Mill Beaters from authorized dealers, distributors, or suppliers across India. Samples are available to help you assess the products quality and compatibility before making a significant outlay.Q: What is the typical application of Hammer Mill Beaters?

A: Hammer Mill Beaters are popularly used for crushing, grinding, and pulverizing a wide range of materials in both agricultural and industrial hammer mills, ensuring efficient material processing.Q: What advantages does the polished, precision-ground surface provide?

A: The smooth, polished finish and sharp, precision-ground edges enhance operational efficiency, reduce abrasion, and help maintain a consistent grinding process, thereby boosting your machines market value.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email